Featured

Products

-

Hour Meters: DP-231H

Hour Meters $12.00 View More -

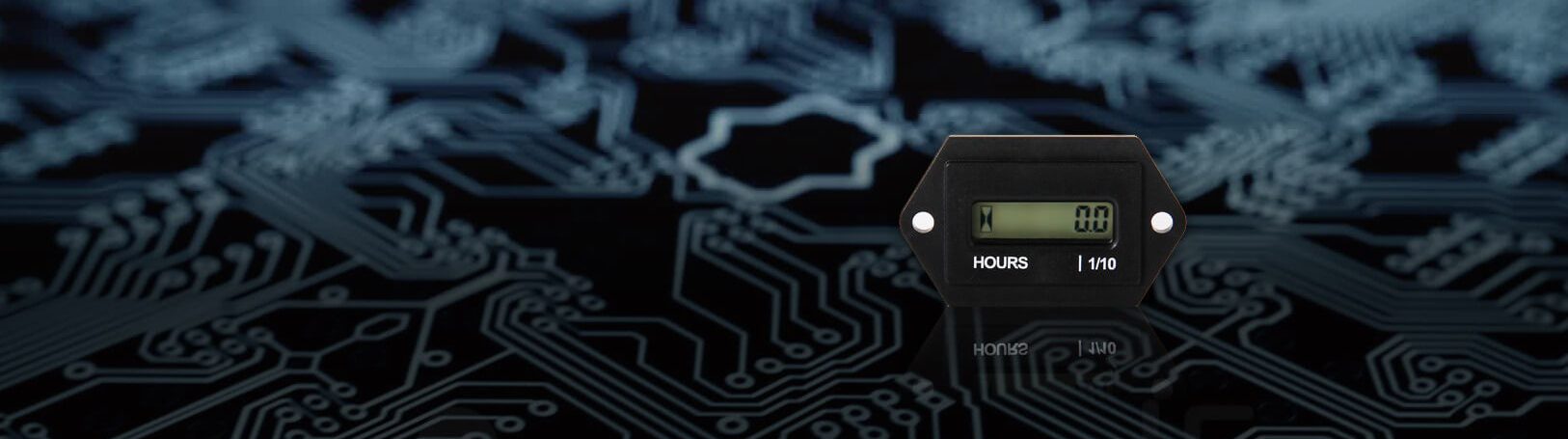

Hour Meters: RL-HM009

Hour Meters $42.00 View More -

3 ½ Digit LED: DP-352

Panel Meters $49.00 View More -

Panel Meters: DPV-3ERN

Panel Meters $96.00 View More -

Panel Meters: DPV-3

Panel Meters $96.00 View More -

3 ½ Digit LCD: DP-52

Panel Meters $54.00 View More -

Count Meters: DHC3J-8L

Count Meters $28.00 View More -

Panel Meters: DP-654

Panel Meters $54.00 View More